Case Study December 3, 2019

Quantifying the Impact of Inventory Optimization

Trexin helped a pharmacy benefit manager use analytics to identify over $18M/year in recapturable lost sales.

Business Driver

One of the nation’s largest Pharmacy Benefit Manager (PBM) operates a mail-order pharmacy frequently used for 90-day refills of chronic drugs distributed from seven national and regional warehouses. Because the pharmacy processes and reporting capabilities related to warehouse inventory management were only semi-automated, there was limited visibility into these processes and a high potential for financial loss related to suboptimal forecasting, including both under-stock and over-stock situations. To help our Client acquire a data-driven, empirical understanding of exactly how much revenue and margin was being lost that could potentially be recaptured, Trexin offered to perform our Actionable Analytics Jumpstart, which is designed to illustrate how to apply advanced analytics and data science to create a decision advantage while executing one or more rounds of rapid discovery and exploration with the goal of identifying an immediate opportunity for action and creating an inferential/predictive model that can later be operationalized.

Approach

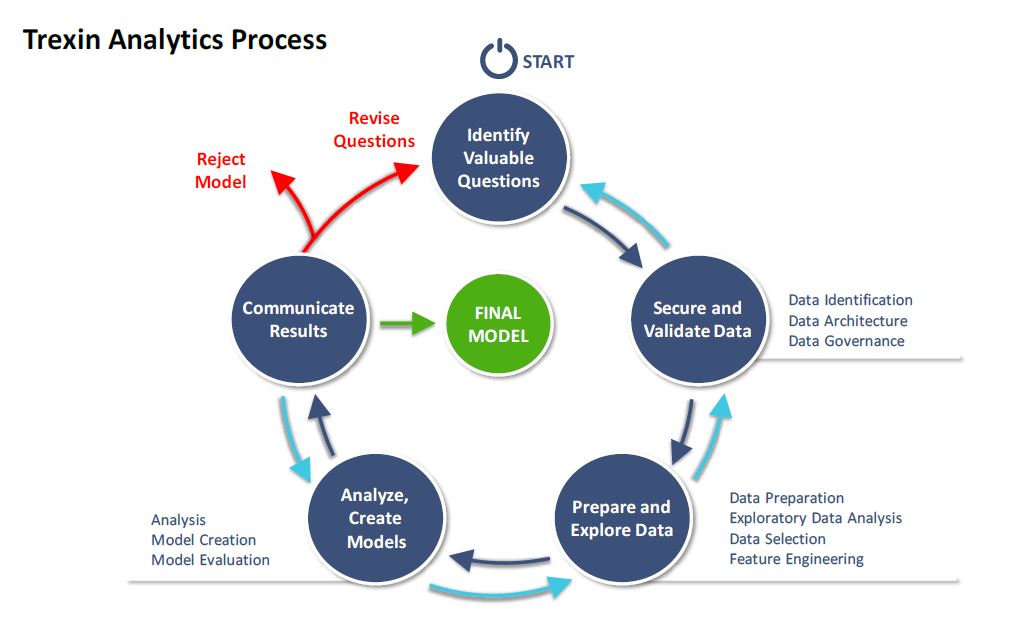

Our approach followed the Trexin Analytics Process, focusing on two large relevant data sets: RxClaim data, and inventory data from the seven warehouses. Trexin first analyzed out-of-stock events by selecting a representative service month where claims data for a 12-month look-back and a 12-month look-ahead was available to analyze what happened immediately prior and immediately following an out-of-stock event. This allowed us to address, quantitatively and factually, exactly how many out-of-stock events occurred, how each of those out-of-stock events were individually addressed (including call-center and Rx transfer costs), and how out-of-stock events affected customer behavior and loyalty. After completing our analysis of out-of-stock events, we then analyzed over-stock situations, focusing on item-level inventory balance to estimate the amount of capital tied up in inventory above the replenishment max (likely due to workload balancing and blanket min/max adjustments causing forecasting issues) and the additional carrying cost of that inventory.

With an empirical understanding of the financial benefits that inventory optimization could provide, Trexin then created a future-state vision for improved forecasting and replenishment processes backed by enhanced analytics capabilities. This vision included new technology components as well as new cross-functional communication and process, with investment levels grounded by a full business case and cost-benefit analysis.

Results

Trexin identified $18M/year in lost sales to retailers due to out-of-stock events, which combined with call center and Rx transfer costs amount to $9.3M/year in lost margin that could be recaptured. Trexin also identified $15M in unneeded inventory spend and carrying cost from over-stock conditions that could be eliminated.